We would like to introduce the voices of customers who are actually using the ANZAI sorter.

≪Request≫

Direct contact with customers will be a nuisance, so if you have any questions, please contact us on this site.Contact FormPlease send to.

Please note that we may not be able to answer depending on the content of your question.

I want you to taste safe, safe and delicious domestic rice ~ LAZ / LCT / LEO ~

We would like to introduce the voice of Shikataichi Shoten Co., Ltd., which collects high-quality rice and beans in the mountainous areas of northern Okayama Prefecture.

Shikataichi Shoten is a collection and sales company that has been making efforts to promote agriculture in the region for many years.This time, we have built a new factory that can optimally polish rice with the germ survival rate using our unique technology.

The eye-catching germ rice has more dietary fiber and vitamins than ordinary rice, which may lead to health, so it will be sold to hotels and health food routes in the prefecture, Keihanshin, Kanto, etc.

Therefore, a high-performance color foreign matter sorter is indispensable for selling high-quality rice.

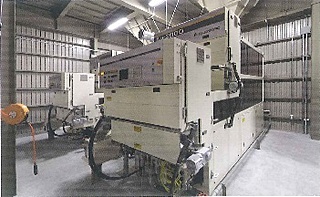

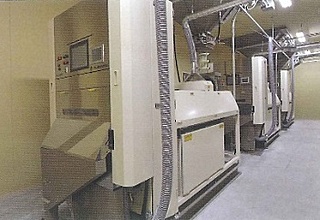

As a finishing touch to the rice milling line, at Shikataichi ShotenLAZ-1605D,LCT-550 Of2.

LAZ-1605DThen, surely remove the stink bug black spot rice and foreign matter, and furtherLCT-550We support the production of various products and produce safer and more secure rice.

We interviewed the Narita Plant Manager.

"It is an indispensable machine for making good products with confidence.

Compared to older machines, the sorting performance is significantly improved, and even small black spot rice and raw materials with a large amount of shirata can be used freely. By using the new sorter, we are able to make better products with more confidence than before.

In addition, the time to process 2t of rice is small enough to be possible to finish it carefully by installing a machine with plenty of room.

'We want you to taste safe, secure and delicious domestic rice.' This is our slogan, and we will continue to make good use of color sorters.

In addition, like the sorter at the rice mill, our bean factory also has our Leo sorter (model).LEO-300D3) Is active.

Unlike rice, we handle a wide variety of varieties such as Dharmasasage, red beans, and soybeans when collecting and selling beans.

Leo sorter is said to play a major role in the selection of a wide variety of beans.

We also asked Managing Director Ashida about his impressions of Leo Sorter.

"We believe that this is a very important machine for making safe and secure products that are close to consumers.

I used to use a fluorescent lamp machine, but it took a lot of time to switch varieties. Also, in this region where the temperature changes drastically, the previous machines were inconvenient because they had to adjust the machines. In particular, warm-up operation and stability of sorting were major issues.

By installing LED in the Leo sorter, I think that not only the problems so far have been cleared, but also the sorting performance has been greatly improved.

While feeling the progress of technology, I expect Anzai Seisakusho to make further improvements."

The idea of Shikataichi Shoten is that it will continue to manufacture and sell products rooted in local agriculture and will continue to contribute to the promotion of agriculture.Through this interview, we at Anzai Seisakusho have renewed our mission to contribute to the world in the category of "selection".

Lastly, I would like to thank Shikataichi Shoten for their kind cooperation in the interview while they were busy.

Voices of surprise for improving yield -LED hyper sorter, LED mighty sorter-

Further quality improvement with LED-equipped machines-LHT / LAZ / RGB-

We would like to introduce the voice of Private City Brothers Store Co., Ltd. located in Hokuto City, Hokkaido.

Private City Brothers Store Co., Ltd. is located in Hokuto City, where the night view of Mt. Hakodate seen from Mt.1956Since its establishment in 31, it has been developing a business related to Japanese "staple food".

In cooperation with producers, we promote safe and secure rice production such as "Dosan Fukurinko", and it is our duty not to allow any compromise in the safety, security and stable taste of our products, and it is a noble mission even if we get tired of it. I'm thinking.

A system has been put in place to install 2 or more color sorters indispensable for providing such safety and security in each process, and among them, the quality required by customers is increasing year by year, so high-performance color sorters are being introduced. In 1 line we use 3 units and hang the product 3 times to make products even safer and more secure.

As the final finishLAZ-1605TThen you can remove everything in the tiny glass removal test, LHT-270 We are very satisfied with the high sorting stability and the ability to accurately remove even minute black spot rice.

When the Sapporo branch opened in the fall of 2016, a foreign body color sorter that uses LED lighting LAZ-1205T and color system RGB-1205 has been introduced to maintain stable product quality.

We received a compliment from the operator of the Sapporo branch, Mr. Kashiwazaki, saying, "A machine that is easy to operate, has stable quality, has little waste, and can be used with peace of mind."

We would like to thank all the employees of the Ichi Brothers Store for their cooperation during their busy schedule.

Rice shop loved by the community-Trinity series-

Introducing this time, Anzai Seisakusho's new sorter "Trinity series RGB-805"You are using it,

"Iwasaki Rice Grain" in Mishima City, Shizuoka Prefecture, commonly known as "Iwabe".

The staple food of Japanese people is "rice", but the taste and price of rice vary greatly depending on the weather and the amount of harvest each year.

"Iwabe" carefully selects and delivers the most seasonal rice, that is, delicious and reasonable rice, regardless of the brand.

This is the reason why the rice "Iwabe" continues to be loved by the Tokai region.

It seems that they pay particular attention to daily quality control so that they can deliver safe and secure rice in a stable manner.

The new color sorter "Trinity series RGB-805"is.We sort out damaged grains such as colored rice and Shirata rice so that you can enjoy them more deliciously.

From the manager, Mr. Kikuchi

"Since the introduction of the Trinity series RGB, it has become possible to deliver delicious rice to customers with peace of mind," I received a compliment.

Thank you for responding to this interview.

Trump card for quality improvement-Hyper Leo Sorter-

Anzai Seisakusho's proud shoot-type full-color digital sorter "LEO-805DC +] Is being used,

We would like to introduce the voice of Hokuriku Recycling Center Co., Ltd. (428 Mizushimamachi, Hakusan City, Ishikawa Prefecture).

Hokuriku Recycling Center Co., Ltd. was established in June XNUMX as a partner company of Hokuriku Coca-Cola Bottling Co., Ltd., and has been developing its business mainly in the manufacture of raw materials for recycling PET bottles.

This time, we have introduced the Hyper Leo Sorter as a trump card for improving the quality level, which is strictly required year by year.

The Hyper Leo Sorter introduced this time is the first in the pet flake industry to have a full-color type + full-spec specifications with a near-infrared camera.

After introducing the sorting machine, we interviewed the president of Hori Representative Director.

As a factor of introducing the sorter,

① Since bidding is becoming stricter year by year, we are differentiating ourselves from our peers.

② Measures for quality improvement that are strictly required by customers

③ Means to survive in this industry

And so on.

We received a comment from a customer that the situation has been very well received and that "the results are as expected."

Also, from Mr. Kondo, the director and factory manager who manages the site,

① Work efficiency is improved because a certain amount can be handled regardless of the quality and mixing rate of raw materials.

② No machine trouble, so no hassle

③ We can supply high quality and stable products to our customers.

We received words such as.

Finally, we would like to thank Hokuriku Recycling Center Co., Ltd. for their cooperation during our busy interview.

Commitment to buckwheat flour from Hokkaido ~ LG-05T ~

"ANZAI Repeater" added the latest foreign matter sorter for rice ~ LRC-1100 ~

Continuing from the previous publication, we would like to introduce the voice of JA Zenno Tochigi Pearl Rice Department (198-2 Hagadai, Haga-cho, Haga-gun, Tochigi Prefecture).

In 2011 JA Zen-Noh Tochigi Pearl Rice Department introduced the LED Hyper Sorter LHT-1100 to its main rice milling line, and 2 years later, the LED Mighty Sorter LAZ-1605T to the sake rice line and the LHT-270 to the glutinous rice line. Are being added one after another, and all three models manufactured by Anzai Seisakusho Co., Ltd. are currently operating at full speed.

Finally, in the fall of 2016, with the new installation of rice milling equipment for major customers, Anzai is proud of the latest foreign matter sorter "LED" to the final process.Rescue sorter LRC-1100 (Maximum processing capacity 11t / h) ”has been introduced.

We asked Mr. Suzuki of the Pearl Rice Manufacturing Division how he came to adopt the same model.

"I have used Anzai's sorter so far, and I have a great deal of confidence in its stable performance, and I have heard the high evaluation of rescue sorters from each business partner, so I decided."

In addition, Mr. Narimi, an assistant factory manager who is also an operator, said, "The sorting machine in Anzai is easier to operate than other manufacturers and can flexibly respond to subtle changes in the quality of rice, which is very helpful to the site. I'm doing it, "he said with a big smile.

That's all, we would like to thank all the members of the JA Zen-Noh Tochigi Pearl Rice Department for their cooperation during the busy New Year holidays.

Quality first with LED-equipped machines-LED rescue sorter-

This time Anzai is proudLED Rescue sorter You are using,

Abe Seimugi Co., Ltd. (Ibarasone, Minami-ku, Niigata City, Niigata Prefecture3701)

.

On Meiji 45 May 1, Abe Seimugi was founded. It is a long-established store that has lasted 105 years.

Manufacture and sale of milled barley and barley flour/contract processing of crushed milled rice/consignment sorting of rice and ship products nationwide.

The main rice milling line at this site has processing capacity 15 t/h Anzai Seisakusho Co., Ltd.'s color and foreign matter sorter is indispensable for owning and continuing to supply high-quality products.

Latest glass compatible color sorter LHT-1800 x2machines, new foreign matter removal dedicated machine in the final process LED Rescue sorter has been newly established and is always operating in the best condition.

The rescue sorter can remove all foreign substances that are difficult to remove even with a glass-compatible color sorter, and is judged to contribute to quality improvement, making it the largest model. LRC-1800 was introduced.

"The first thing we think about is product quality."

Due to the nature of Niigata, the factory is used at extremely low temperatures in winter, but allLED Because it is an on-board machine, it starts up quickly and the light source is stable all day, which was highly evaluated by the factory manager Kondo.

"When I was using a fluorescent lamp sorter, it was difficult to stabilize the sorting all day and it required a skilled worker," he recalls.

It seems that there are many requests for consignment sorting because we have a line that can ship products from which all foreign substances have been removed through a color sorter / foreign matter removal machine.

Abe Seimugi's factory is organized and tidy no matter when you visit, and you can feel a strong desire to improve quality.

Lastly, we would like to thank everyone at Abe Seimugi Co., Ltd. for their cooperation during the busy schedule.

For customers who can see beyond wheat and rice ~ Rescue sorter ~

Many in the factory to maintain high quality use the ANZAI sorting machine, but the "rescue sorter" is the last bastion of finishing sorting.

The rescue sorter is a foreign matter sorter for white rice equipped with a special camera that reacts only to foreign matter. It is a machine that checks and removes foreign matter that cannot be removed even with a glass sorter, and bran and insects mixed in the line just before bagging.

Developed a camera for barley in response to a request that barley could be used because of the sympathy for the rescue sorter concept. After several tests, it was determined that we could ship higher quality wheat than ever before, and it was the largest channel. 240 ch was introduced.

To date, it has greatly contributed to maintaining product quality.

Takahata Seimugi will continue to ship safe products for customers who can see beyond wheat and rice.

Finally, thank you to Mr. Takahata Seimugi Co., Ltd. for your cooperation in the interview.

Further safety, security and stability-Au, BMR, BLC, etc.-

From Yoichi Town to the whole country-Magnet Stoner-

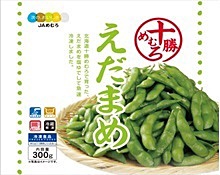

We collect azuki beans harvested in rural areas and commercialize the whole amount by machines in the factory.

In addition, for buckwheat noodles, which are considered difficult to select, foreign substances such as stones and iron mixed in during cutting have been dealt with.

We decided to introduce BMR based on our belief that we would like to maintain higher quality and provide our customers with peace of mind and safety.

At first, there were some doubts, such as the removal of stones by magnetic force, but the effect was immediately demonstrated after the introduction.

Pumice stones can be removed by actually pouring the raw materials! BMR has made it possible to remove pumice stones, which is considered difficult in specific gravity selection.

Due to his success, the color sorter in the subsequent process made me say, "The stones are almost gone." Nowadays, 3 BMR-100s are in active use, and we have earned tremendous trust that we can have any number of them.

Thank you very much, Mr. Saburo Hiratsuka, for your busy schedule.

Bring your favorite Chirimenjako to your table ~ Real Sorter ~

Two years ago, in the Chirimenjako industry, the problem of puffer fish fry contamination was highlighted, but by introducing a color sorter early, it was possible to deal with it without reducing production.

To ship high quality vegetable seeds ~ LEO sorter ~

I want to deliver safety, security, and deliciousness ~ Leo Sorter ~

Mimata sesame seeds nationwide-Real Sorter-

This time, from Mimata Town, Miyazaki PrefectureReal sorterWe would like to introduce the voice of Mr. Masaaki Shimoishi, the representative of "Shimo Farm" who produces the sesame seeds and delivers them nationwide.

In recent years, when foreign substances have been mixed in, the standards for Japanese food have become more and more stringent.

In particular, agricultural products produced from the blessings of nature require stricter inspection.

"I want to deliver healthy, delicious, safe and secure sesame seeds to your table !!"

There was a one-sided feeling of Representative Shimoishi.

However, it is not very easy for humans to visually inspect sesame seeds, which are smaller than rice grains, one by one, and it may take a day to sort them.After introducing the color sorter, Mr. Shimoishi thanked Mr. Shimoishi, saying, "I can now spend the long time I was working on sorting work on other work, and I can now produce more stably." We are doing it.

Thank you for your cooperation, Shimo Farm.

Commitment to quality that overturns common sense in the industry-Belt type color sorter (BLD)-

Anzai Seisakusho's multi-purpose optical systemMasakazu Clean Co., Ltd. (Chojabara, Onomichi City, Hiroshima Prefecture) using a sorting machine1-220-7) Will be introduced.

The history of Masakazu Clean Co., Ltd. started from the general waste treatment business.1981Go back to the year.2005Years4In May, Onomichi will utilize the technology and corporate foundation cultivated up to that point.PETStarted operation of bottle recycling factory.

Used from the island of Onomichi in Setouchi, which is not connected by a bridgePETI'm collecting bottles.Of such an islandPETThe bottles are clean, but the ones that are collected from other places are still conspicuous, with dirt and foreign matter mixed in, and those with labels left.

Many of the machine lines in the factory are original, and we make use of our unique ideas and cultivated know-how to make improvements through trial and error to produce high-quality products that meet the needs of our customers.Among these machinery and equipment, the one that has received particular attention from the industry is"Belt Type Color SorterBLD-1200S5( 2 t/h specification)".

The original reason for the introduction started with a letter of invitation from Anzai.

"Quality is the most important thing we think about. Cost should be considered afterwards. Otherwise, we cannot win the trust and peace of mind of our customers. With this color sorter, high quality The amount of our flakes finished in this product is increasing year by year, and they are processed into textile products, sheet products, and container pack products, "says Murakami.

The quality of the flakes delivered by other companies in the same industry is poor, and the manufacturer of the delivery destination often asks for color selection. “We will continue to take on challenges with innovative ideas, action, and eco-power following the introduction of color sorters,” says Kimura, general manager of the PET Recycling Division. I felt the enthusiasm of all employees to work together to create high-quality products.

Next year, he is preparing for the automation of PET bottle sorting, which is struggling with multiple manpower at the beginning of the line.

Lastly, I would like to thank all the staff of Masakazu Clean Co., Ltd. for their cooperation in the interview, despite their busy schedules.